VAN WINGERDEN GREENHOUSES

WEEK 6 NEWSLETTER

Hello to the Horticulture Industry!

We are excited to be running into Spring with you and would like to update everyone on Van Wingerden Greenhouses shenanigans.

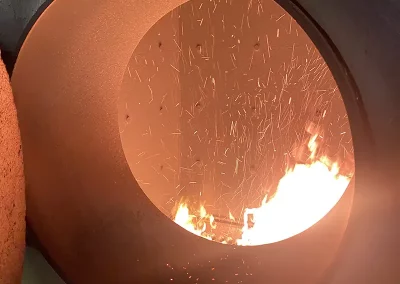

HEATING:

January 1 was met with a serious challenge. Natural Gas is our primary source for heating our greenhouses and the west coast is on an isolated pipeline. The demand on our pipeline has been incredibly high and supply depleted. This resulted in a historically high price for us in January. Up 4 times the previously highest ever price we had encountered.

To combat this challenge, we have been double insulating walls, consolidating into the least amount of houses possible and running 24 hours supplementing our heat with our wood boiler. Fortunately, we had also booked approximately ⅓ of our fuel on a long term contract which brings our average price down, but only on the first third of the natural gas that we consume.

All of this being said, we have been making some sacrifices to keep our cost down to survive, and some products have had to live in an environment that may not be ideal conditions. We were finally in a position to open another greenhouse with better LED lighting and optimal temperatures this week. This gave us better root systems and more compact top growth. Thank you for being patient with us through these challenges. February is looking much more manageable!

HIGH QUALITY CUTTINGS

We have been extremely pleased with cutting quality this season. The farms in Central America have gone above and beyond to supply us with consistent and quality cuttings this season. There have been some isolated issues of course, but 2023 is off to a much better start than 2022.

On the other hand, we have been seeing URC bag counts being off since the beginning of the season, we are communicating the shortages every Friday or as soon as we are done sticking, some of you might have received emails from Margaret Gianquinto reporting shortages, substitutions or rebookings already, the farms are aware and they are working on getting this fixed.

We also looked into getting some buffer in for some of these problem items that are being shipped short, but unfortunately the farms are requiring the buffer to be paid for out of our own pockets. We do not have this extra cost built into any of our items, so we will be unable to solve the problem this way. Feel free to send us any suggestions you think might be helpful.

SEED SUPPLY AND GERMINATION:

One of our goals for 2023 has been to further control our seed inventory and to start early with seed procurement. We have partially solved our issues by bringing seed in earlier and managing our seed inventory much tighter.

Not all issues have been foreseeable, but we do feel that we have solved a lot of our past problems with this new approach. I think there are some adjustments for next season, but we are currently in a great position for this season.

Germination started off really well and we began this season with some generous oversow factors to make sure we were hitting the mark on our more challenging crops. On occasion we have had some issues with different seed lots or unexpected issues in germination, but we are confident in our current strategies to manage our germination.

CUTTING STICKING PROCESS:

We have also recently implemented a new tracking system at our sticking line. The goal is to have ultimate traceability back to the individual that stuck each cutting. This allows us to do several things.

We can now see how many trays each employee is sticking per hour to make sure we are keeping our cost down. This has been a problem as there was no real way of seeing how efficient we could be at our sticking line. Each employee has an individualized barcode that they stick on the front of each tray. Once the trays are stuck and moved to the transfer rack, we scan the trays to confirm that everyone is keeping up to the expectation set by the line leader.

We can also track down any sloppy stick jobs back to the individual to correct any human error. If we notice specific trays are not performing as well as others we can return to the person that stuck that tray to make sure they are properly trained and operating as expected.

DIVISIONAL SUPPORT:

Another effort this year has been to use our product lines in our Finished Product Division to help support our Young Plants Division. The diversity in our business will help strengthen each individual division.

The strategy is to use our products in our finished division to consume overage that is produced in our Young Plants Division. This has always been done in a small way, but was never as purposeful as it is now. Now we are planning a portion of our total production to actually be pulled from the waste in plugs and liners.

This allows us to increase our oversow on critical items without risking too much waste. We are able to use products like mixed bowls or mixed baskets to consume the overage without risking our bottom line. A true lemons into lemonade situation!

OTHER NEWS

We worked with BallSeed this past week to put together a short video highlighting our Gold Supply Operations.

We are excited to partner with Ball on this project and appreciate everything they do for us.

Thank you all for the hard work and support! We know we are coming off one of the most challenging years in our history.

Both weather and supply issues were abundant last year and the pain has definitely helped us to learn a lot about how we can improve.

Feel free to give us a call or drop us an email anytime.

– Thank you from the Van Wingerden Team